Light Guard Installation & Testing

Successful machine guarding can be a complex issue with a need not only to comply with the regulations but also to maintain the capability of the machine to perform its intended task.

Successful machine guarding can be a complex issue with a need not only to comply with the regulations but also to maintain the capability of the machine to perform its intended task.

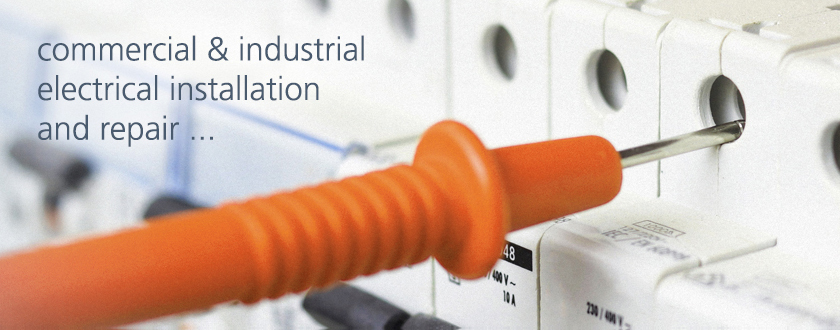

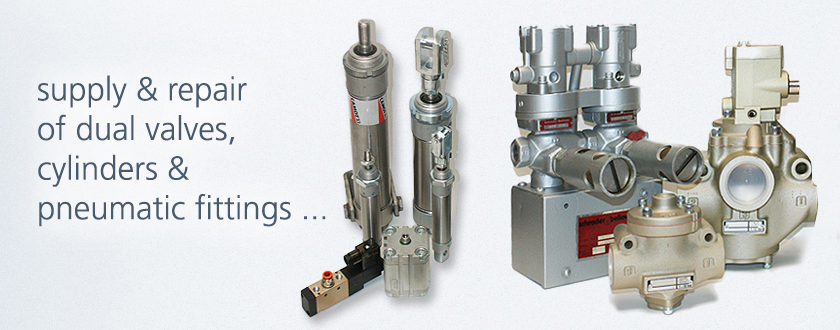

It may be necessary for a combination of machine guard types to be used together to effect the ideal solution. For example; fixed fencing is frequently used in conjunction with safety light curtain systems to provide safe working areas where access is also required; by adding safety interlock switches / safety mats / safe edges and sensors at strategic parts of the machine you may also be able to enhance the usability of the complete guarding system. Here at Flangecombe we can assist you with the right type of guarding for your machinery.

Testing

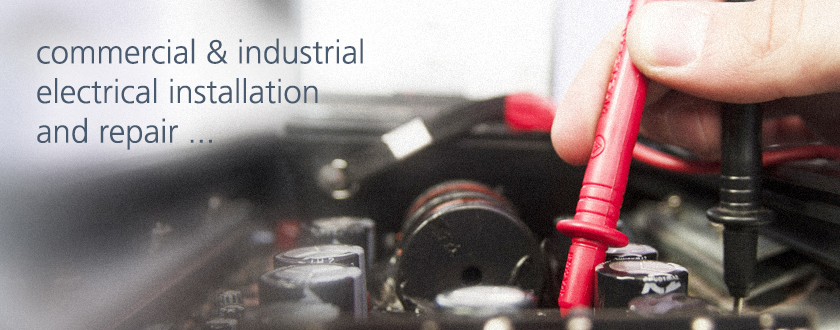

At Flangecombe we also have the equipment to do periodic testing of your light guard equipment, to ensure correct alignment, and position of the guarding to comply with current regulations. Our equipment is designed to measure stop time, stop distance and velocity of power driven machinery like presses, robots and other machines with user access. In accordance with national and international safety standards machines with dangerous movements have to be equipped with protection devices. The improper placement of a protection device (2-hand control, safety light curtain and so on) will result in the potential for injury of the operator.

The improper placement of a protection device (2-hand control, safety light curtain and so on) will result in the potential for injury of the operator.

All the important measurement values such as stop-time, stop-distance and velocity are provided to calculate the minimum safety distance.

The safety distance is defined in national and international standards like EN ISO 13855 (EN999). To ensure maximum safety the stop-time measurements have to be repeated periodically (6 months).